An Origin Story

Where It

All Began

By Rob Howard, Founder and CEO

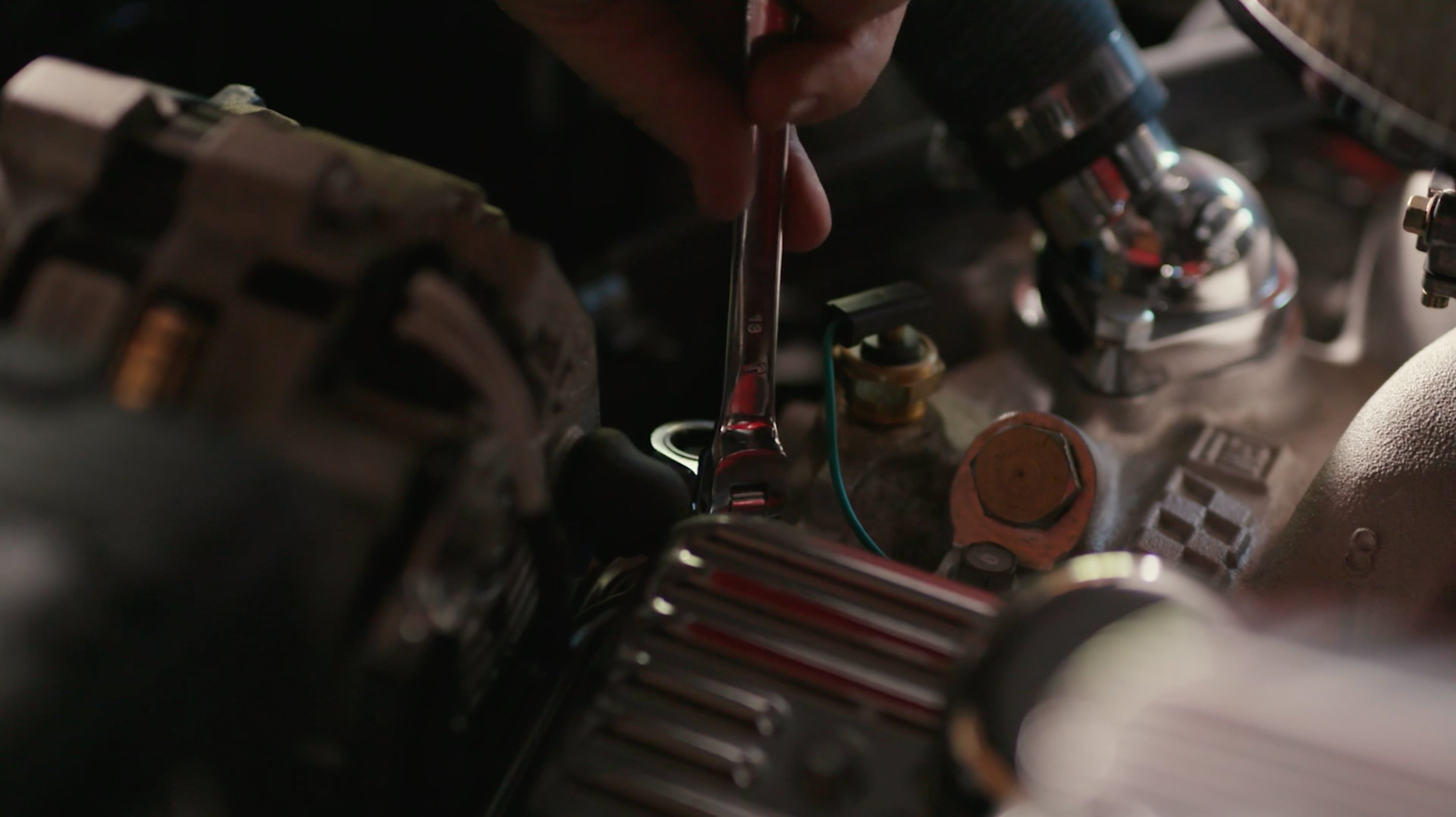

My automotive love started early — with Matchbox cars, a Road & Track subscription, and Porsche 911 posters taped to my bedroom wall. But it really took root under the hood of my dad’s car.

Growing up in Philadelphia, whenever something broke in our house, it was me, my brothers, and my dad who grabbed the wrenches, got our hands dirty, and figured out how to make it work again. That instinct — to fix, to learn, to bring something back to life — became a lifelong passion.

"As rewarding as restoration is, it quickly became clear how broken the process was."

The Spark That

Started It All

About 25 years ago, I began restoring vintage cars in my garage and quickly discovered that while the work was rewarding, the process was fragmented, time-consuming, and frustrating, with more effort spent planning and re-doing than actually enjoying the drive. That reality hit even harder in 2015, when I set out to restore my beloved Chevy Bel Air after it had sat in the desert for 32 years. What I hoped would be a dream project turned into a four-year odyssey of chasing down vendors for engine work, bodywork, paint, and upholstery, navigating a maze of YouTube tutorials, shipping delays, and unanswered questions. That's when it hit me: there had to be a better way.

“What if restoration were streamlined, transparent, and modernized, so enthusiasts like me could spend less time chasing parts and more time enjoying the drive?”

The Start

Opening the Garage Doors of Kindred Motorworks

Having spent my career building and scaling technology companies, I couldn’t help but see the opportunity. I brought together the team I’d worked with at previous ventures, and together we began building the operational backbone the restoration industry had long been missing — integrating systems, technology, and scalable processes that traditional shops simply didn’t have the resources to implement. In 2019, we opened our first small facility in San Rafael, California. It was scrappy, collaborative, and full of moments we’ll never forget — including a lost wheel on the Bay Bridge and countless margaritas at Celia’s. Those early days taught us how to solve problems fast and keep moving forward.

From the start, we knew we wanted to go beyond cosmetic rebuilds. Engineering excellence and electric drivetrains became core pillars of our approach. To truly enjoy a vintage car, it had to be safer, more reliable, and undeniably fun — outcomes that required deep technical expertise. Electric platforms meant greater reliability, better performance, simpler maintenance, and a sustainable footprint for generations to come.

We’ve come a long way from that first garage in San Rafael.

2023

Kindred's First Vehicle Delivered on Mare Island

After spending two years designing, engineering, and prototyping Kindred's vintage Bronco restomod, the model officially went into production. The keys to Kindred's first gas Bronco 001 build were handed over to the new owner.

Our Unique

Business Model

As exciting as our cars are, the business model might be even cooler. We’ve built a flywheel of R&D that designs new models every year, with dozens of engineers and millions invested in OEM-level testing. Each launch feeds into the next, accelerating development.

Our proprietary technology platform, BLUEPRINT, captures the knowledge of our master mechanics and standardizes every process from supply chain to production. When off-the-shelf parts fall short, we design our own — like the Grayback EV platform, named after a historic submarine built on Mare Island. Grayback is the most advanced electric conversion platform in the world, powering our cars with cutting-edge controls, HVAC, and charging systems.

Restored and Reimagined

We honor the soul of classic cars while equipping them with the comfort, reliability, and performance that drivers expect today. Bluetooth stereos, engineered brakes, modern suspension, electric drivetrains — all designed so our customers can do what matters most: enjoy the drive.

We’re not just building cars, we're building a movement — one that removes every barrier to owning and enjoying a vintage vehicle.

I hope you'll join us

Because at the end of the day, this isn’t just about fixing cars. It’s about freedom, connection, and the simple joy of being behind the wheel of something timeless.

- Rob Howard