A journey from our roots to the latest limited edition release

Building the Kindred Brand

When we think of Kindred, we think of kindred spirits and the cars we grew up with, the ones tied to our strongest memories. As new models arrive, those classics are too often left behind. At Kindred, we bring them back to the road, blending nostalgia with modern engineering so you can relive the past in the present.

By investing in thoughtful engineering, purposeful design, and meticulous craftsmanship, we’re bringing them back to the everyday drives they were built for. At Kindred, quality isn’t a buzzword. It’s the work of our hands. We build these vehicles ourselves, not with robots, because craft matters.

If there’s one thing that defines the Kindred brand across everything we do, it’s our people. It's their skill, their passion, and their commitment to doing things the right way, every time.

Investing in the Future

From day one at Kindred, we knew EV had to be part of the story. As a powertrain for vintage vehicles, it offers less maintenance, easier service, and a future-forward way to keep these classics on the road for years to come.

After digging into the EV options available for vintage vehicles, we didn’t find anything we truly trusted. It became clear we had to build our own platform—and make it the best in market.

So we built an engineering team from the ground up, focused on designing and testing proprietary components you simply can’t buy off the shelf. That work began in 2021 in our original San Rafael, CA HQ, where we also put our first four prototypes on the road to kick off real-world R&D. Those first prototypes were the ICE Bronco, EV Bus, and EV Chevy 3100.

Scaling Our Company

With our Founder Rob's background in building software companies, he knew he wanted to bring that same skill set to Kindred. This was the genesis of Blueprint. Blueprint is Kindred’s digital backbone, a suite of software tools that turns every build into a clear, systematic workflow. From the first work order to final assembly, Blueprint connects teams across all departments and keeps everyone aligned on what’s happening, when, and by whom.

It delivers detailed work instructions for every step of the build and tracks progress in real time, helping us scale production without ever compromising on quality.

As a result, Blueprint has enabled Kindred to create new jobs in a structured, scalable way that gives technicians a clear path to grow their skills and feel supported along the way. It’s also become a powerful decision-making tool, helping the team use real data to determine which models we should build next.

Kindred's First Customer

In February 2023, we graduated from a small garage in San Rafael, CA to a 100,000-square-foot facility on historic Mare Island. It was a turning point for Kindred, a move that signaled real momentum, a growing team, and the ability to scale from a handful of builds to true production.

Mare Island gives us the space and infrastructure to do what we’ve always envisioned: engineer, test, and build vintage vehicles at a consistently high standard, all under one roof.

By December 2023, we reached another major milestone: handing over the keys to our first Kindred customer, who drove home their tangerine ICE Bronco Heritage Edition.

From a garage operation to delivering our first production vehicle in just three years, Kindred has gone from idea to ignition and proving that our vision for reimagined classics doesn’t just live on the drawing board. It lives on the road.

All Things EV Bronco

In 2024, we took everything we’d been learning in design and R&D and brought the Kindred EV Bronco to life. Year four was a turning point for Kindred on the electric front: our in-house EV platform made major strides, and four EV Bronco prototypes hit the road for real-world testing.

As the miles stacked up, so did the validation. Our work at the intersection of classic design and modern EV tech started to attract serious attention which culminated in a feature from GQ that recognized Kindred as a leader in electric innovation within the classic car world.

We closed out the year with a milestone we’d dreamed about: showcasing our EV Bronco prototype on the concept lawn at Monterey Car Week. That moment represented thousands of hours of engineering, testing, refinement, and iteration. Year four was defined by relentless progress and it built the foundation for the growth, scale, and expanded EV offerings we’re driving toward next.

EV Bronco First Customer

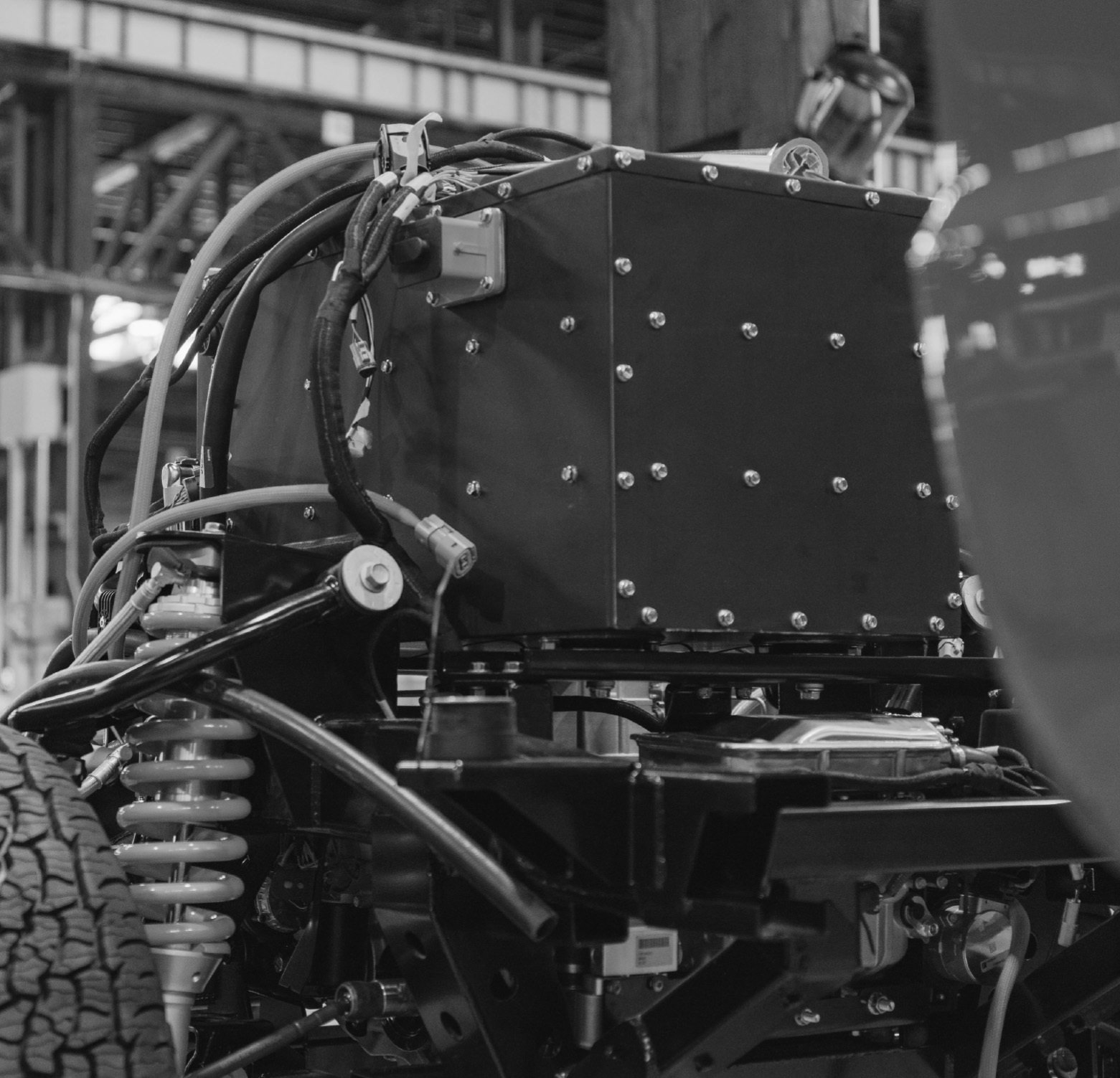

In 2025, we put our first electric vehicle into production: the Kindred EV Bronco. By September, the very first EV Bronco rolled out of our doors and into the hands of its new owner. This was a milestone years in the making.

That delivery also marked the official launch of our in-house electric vehicle platform, Grayback EVP. It’s a true engineering achievement with OEM-level quality, designed from the ground up to bring modern, reliable EV performance to classic vehicles. and it’s something we’re incredibly proud of.

2025 was also the year we began building out our national dealer network, starting with locations in Texas and California. This expansion laid the groundwork for stronger service and support across the United States, setting us up for broader reach and even better ownership experiences in 2026 and beyond.

Limited Edition 5 Year ICE Bronco

Five years in, and the road ahead is looking really good. And we've only just begun.

To celebrate our five-year journey, we’ve created a Limited Edition ICE Bronco that embodies everything Kindred stands for: engineering obsessed with detail, design that honors the past, and craftsmanship refined with every build. Black and white define the Kindred brand and are made bold on this limited edition.

We’re building just five.